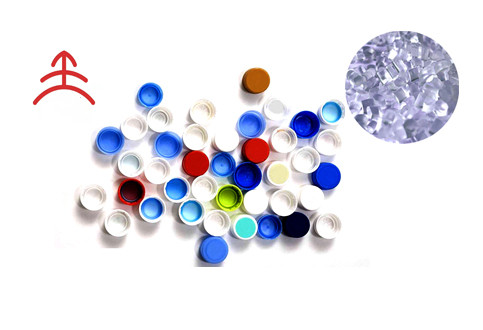

Description:

Thermoplastic elastomer materials can be produced in large quantities by injection molding equipment, and the scraps and spout produced by injection molding can also be 100% recycled, easier to process than silica gel, cost saving, and more environmentally friendly than PVC. At present, The products could meet the requirements of food and drug packaging test, and can meet the requirements of drop molding. And almost 100% stopper and cap liner for drinking bottle are TPS in the market.

Advantage:

1,TPS is food grade and environmentally friendly

2,TPE elastomer can be recycled to effectively save energy, is the ideal material to replace rubber and silica gel.

3, The property is relatively stable, with good temperature resistance (use temperature range -30-60℃)

4, Excellent coloring, soft touch. TPE material does not introduce heavy metals and does not add 5, Toxic phthalate plasticizer in the production process, which conforms to various environmental testing

6, Energy saving, improved production efficiency, short molding cycle

7, With high elasticity of rubber, but also has the characteristics of direct injection processing

8, Can be two injection molding, with PP, PE and other matrix materials coated bonding, can also be formed separately.

Specification Property:

ADDRESS:ADDRESS:No. 151, Yangyu Street,Suzhou/Shanghai, China.

E-Mail:info@hlz-tpe.com